Sumerian Coefficients at the Weavers Factory and eTCL Slot Calculator Demo Example

Sumerian Coefficients at the Weavers Factory and eTCL Slot Calculator Demo Example

This page is under development. Comments are welcome, but please load any comments in the comments section at the bottom of the page. Please include your wiki MONIKER and date in your comment with the same courtesy that I will give you. Aside from your courtesy, your wiki MONIKER and date as a signature and minimal good faith of any internet post are the rules of this TCL-WIKI. Its very hard to reply reasonably without some background of the correspondent on his WIKI bio page. Thanks, gold 12Dec2018

- Sumerian Coefficients at the Weavers Factory and eTCL Slot Calculator Demo Example

- Preface

- Introduction

- Table 1, Garments text from Ur III

- Table 2, Sumerian coefficients for daily work quota, includes math problems and implied constants from tablets etc

- Table 3, Sumerian colored garments

- Table 4, Surface density of Modern or Historical Fabrics

- Table 5, Pseudocode and Equations using coefficients

- Table 6, Formulas below are from modern times, more or less.

- Table 7, Formulas below are from ancient times, more or less.

- Testcases Section

- Screenshots Section

- References:

- Appendix Code

- Comments Section

Preface

gold Here is some TCL calculations for materials and workday quotas of ancient Sumerian weavers. The impetus for these calculations was checking garment weights in some cuneiform texts and modern replicas. Most of the testcases involve replicas or models, using assumptions and rules of thumb.

Introduction

One tablet cites 7 tug2-sagusbar garments weighing 25 manas of wool and 4 small tug2-didila garments weighing 12+1/3 manas of wool. A mana is equivalent to 0.4977 kilograms or 497.7 grams. Using proportions, one finds 25 manas/ 7 sagusbar garments or 3.5714 mana per sagusbar garments. For the small garments (12 + 1/3)/ 4 small tugdidila garments or 3.0833 mana per tugdidila. The tug2-sagusbar (lit. cloth good [quality] woven [around] middle) appeared equivalent to the high status female garment (long skirt) and equivalent to the tug2-bar-dul ( long skirt, full body garment). The small tugdidila (literally, cloth small small carry [children] ) was probably the garment of female children. At least on this tablet, the individual garments weight from 3.08 to 3.57 mannas, converting to (3.08*0.4977) and (3.57*0.4977) kilograms. The cited individual garments weight from 1.53 kg to 1.777 kilograms.

Another tablet cites 3 tug2-sagusbar garments as a daily quota. That is, a weaver processes about 3*3.5714, 10.714 manas a day, or 5.332 kilograms of wool per day. Since there are other types of garments listed as daily quotas or weights of cloth, this key allows a provisional scheme to assess garments relative to the weaver's workday and weight of wool.

Now the workday equivalent for the woolen goods can be found. The workdays for the weaver was 7 tug2-sagusbar garments times 0.314 workday plus 4 tug2-didila garments times 1.53 workday, 2.198 + 1.132, or roughly 3.3 workdays.

In occasional texts, individuals received wool rations or wool payments. Variety of payments would be high status (4 mannas), women weavers or other craftsmen ( typically 3 to 3.5 manas), hired men or women (2). In some cases, the wool ration was listed with other workers receiving yearly clothing allowance, but other occasions seemed to be a perk of a high status job, even foremen of construction jobs (3-4 mannas). At least for the women weavers and craftswomen, the wool ration of 3 mannas was close to nomimal amount required for the female garment or long skirt. One tablet indicated some wool rations distributed to a number of women etc on the 12th month. Presumably, the wool rations were distributed and woven before the Aditu festival in the first month of the year.

For the low status men, the wool ration of 2 manas was probably enough to furnish a lam cloak and a loincloth. The fourth class lam cloak was about 2 manas in weight. The research could not find an overt Sumerian text on weight of loincloths, but there are garments listed as "tug2usz-bar ge6 42 tug2 u4" which were small cloths made as 42 items per day. The Nippur lexical list etc notes candidates as tug2-nin-nes (cloth loincloth ), tug2-ib-pes (thick hip garment), tug2-nin-dara ( sash), nín-dara-gala-sír-ra: ( woman napkin) and tug2-bar-si ( sash). At Ur, the tug2 sag usz-bar 38 tug2 per u4 was 38 per workday. Using proportions, the weight of the loincloth would be 5.4 /42 or 0.129 kilograms or 0.254 manas. Cdli 2009-2 showed two prisoners provided with tug2-u-ge8 [ black "u" garments] and probably not luxury clothing, so perhaps a tug2-u-ge8 garment is a black loincloth. Black (ge8) is interesting wrinkle, whether natural or dyed black wool. Perhaps tug2-u-ge8 and tug2-usz-bar ge6 are nearly the same item, a black wool loincloth.

In the accounting texts, there are tallies of shepherds and overseers turning in amounts of wool. Usually these texts tell the amount of wool in manas and the exchange value in silver pieces or other products. A silver shekel bought 9 to 12 mannas of wool or 30 to 40 manas of goat hair. Each sheep or goat provided roughly 2 manas (~ 1 kg) of wool or hair. For comparison, modern sheep like the Merino produce 8-12 kilograms of wool.

In the the URIII accounts, there are terms for wool (siki) and grades of lesser quality wool which were rated in silver values. The value of wool has been estimated to range from 9 to 13 manas weight for one shekel of silver. Reasonably, a silver shekel would purchase more weight of the lower grade wool (say 10 to 13 manas). While some tablets in the CLDI library have broken pieces, faint words, and abbreviated terms, one can run a search in the CLDI library and pull out instances of lesser quality wool (siki mug-bi), meaning positive occurances of mug-bi as opposed to plain siki alone. The understanding has been that siki-mug contained more short hairs than regular wool. It is known that some wool was salvaged from carcases, and may have been rotten or undesirable.

There are different qualities associated with wool in the text, including siki mug (poor quality wool). Elaborating, siki mug is a low quality wool with short and broken wool fibers (also mug, muk,mu, Akk. mukku). In the CDLI equivalencies list, there is a garment tug2nig2-lam2 du (cloth_item cloak built felt?) which has a daily quota of two workdays. The term "du" in context with cloth is usually associated with felt. For example in the Nippur lexical lists, there are clothing terms tug du ( cloth felt), tug guzza du (cloth neck wrap felt [shirt?]), and tug du-a-ibiba ( cloth felt belt ). Most of the felt production in published texts were high class garments and many workdays, which are difficult to evaluate in terms of simple felt cloth production. As a first cut and combining the information, the production rate was roughly 5.3 kilograms of felt cloth per workday, similar to the weaver production rate.

Another Sumerian textile term was siki za-ri-in (poor quality wool). In the CDLI library, there were 31 instances of combined siki, za-ri-[in], or za-ri-[in]-bi, mainly in URIII accounts or inventories. The "-bi" is third person genitive that was used in the equivalency formulas and here was used not as [noun<3ird-p-genitive] but as [noun<adjective<3ird-p-genitive]. Normally, the "-bi" construct acts on the same or a preceding line in the tablet. In the za-ri-in searches on the CDLI library, there were "-bi" constructs that appeared to act on more than one preceding line. "siki za-ri-[in] -bi " (its poor quality wool) was occasionally used as an equivalency to give numbers of garments and the equivalent weight in manas of poor quality. There were other instances where a tablet line would give weights of siki za-ri-in and the type or number of garments ( possible equivalency statements, but not using the "-bi" construct). Tentatively, it appears that either these garments were being salvaged or reworked for the wool content or were included in inventories as poor quality wool.

Tablet KVM 32.1182 was published in CDLI 2007-001 and was especially fruitful in giving weights of garments and textiles during URIII. From the more legible entries on KVM 32.1182, the average weight of Sumerian cloaks and robes can be tallied. The tug2-lam cloak was found to weight 8 for 10+7+2/3+3*(1/60) manas, which gives 32.716/8 or 2.214 manas. The tug2-uz-bar garment was found to weight 4 for 10+5+10/60*1/60 manas, which gives 15.0/4 or 3.75 manas. The tug2-guz-za-du felt garment was found to weight 4 for 20+1+1/3 manas, which gives 21.333/4 or 5.333 manas. The tug2-guz-za woven garment was found to weight 6 for 32+5/6+5/6*1/60 manas, which gives 32.847/6 or 5.474 manas. In other documents, the workdays are given for tug2-guz-za etc of high status garments, which are difficult to break down in terms of workdays spent on a mass of wool. Also, it is not established whether the workdays for the garments include all the tasks of washing, carding, spinning, dyeing, and weaving.

The base 60 numbers in the Sumerian texts are tricky to read correctly, so it is desirable to cross check magnitudes (in the eTCL calculator) with some replica loom results. The results of carding wool, spinning wool and weaving a fabric on a replica vertical loom were converted into metric kg units and the Sumerian workday (12 hours long). The wool was washed prior to spinning yarn and lost about 6.7 percent weight in washing. After washing, approximately 66 grams of wool were carded and combed after 9 hours. Converting to 12 hour workday, the rate of carding wool was 88 grams per workday. From the replica weavers, here are some average figures for spinning yarn converted to the 12 Sumerian workday: 22.39 grams spinning yarn per workday, 27. grams per workday, and 24.7 grams per workday. On the available yarn records for the replica loom, the total yarn weight was 31.1 grams and yarn length was 515.3 meters length. The wool fabric left on the loom was 0.24 meters by 0.07 meters. That is, the loom weights with the vertical warf threads were spaced over an interval of 0.24 meters and the weavers travel down the loom (with the shuttle) was 0.07 meters. The replica wool fabric was noticeably thin and transparent, but probably would qualify for a light weave like gauze. For the replica fabric, the surface area over weight was roughly .0311/(0.24 m* 0.07m) or 1.85 kg/sq meter. (The above notes do not assert that vertical looms were used at UrIII and earlier, only the wool preparation processes and fabric density are compatible with the texts.)

The clay tablet BM 85194 has a math problem that one woman wove a length of cloth for 20/60 rod or 2 meters in a day, presumably on a loom. The width of the loom was not stated. However, since a single person can hardly weave a greater width than arms reach, a 1.2 meter width would be near the upper limit for one person. Since the loom product or rolls were shipped in 60 liter baskets about 0.5 meter high and 0.5 meter diameter, the loom width was probably from 0.5 meter to 1.2 meter, as an order of magnitude. In the same math problem, there was a description of a cloth bolt that was 48 rods, converting 48*6 to 288 meters. The total labor of the cloth bolt was 144 days and the daily weaver labor was a fraction of a cloth bolt, 1/144. The fraction 1/144 can be expressed in Sumerian fractions (base 60) as 25/3600. There was not enough information here to completely solve the loom dimensions or daily loom quota. Given all the assumptions, the tentative daily quota off the loom was at least 2.4 m*m, 2. by 1.2 meters, or roughly 4 cubits by 2 cubit.

In one coefficient list, there was a constant for wool (sa-hi-a) as 48. The term hi-a appears in URIII texts associated with wool and textiles, and possibly means processed wool, processed fleece, or derived from work of wool [treated with] water. In the Nippur lexical lists, the term siki al-hi-a was translated as processed wool [work]. In the coefficient lists, there are large numbers that give the numbers of baskets and other products from a standard reed bale of 480 reed bundles. For example, there is 298 90-liter baskets from 480 reed bundles, 320 60-liter baskets from 480 reed bundles, and 432 reed mats (1 sq. m) from 480 reed bundles. Since processed wool was counted in manas, possibly the wool constant means 48 garments from the standard wool packs of 60 or 90 manas. The possible garment would weigh either 60/48 or 90/48 (1+5/6) manas. Looking over the known garments, only the lam cloak fourth class really matches the conditions by weighing just under 2 manas. The lam cloak was produced in large numbers and the wool ration of the low status men (2 manas) would cover the necessary wool for a lam cloak (4th). The female garment or long skirt weighed about 3 mannas and does not seem to match.

The tug2 cloth as a textile bolt of 192 square meters from the weaver shop would probably be shipped in either a 60-mana load or 90-mana load. Since the weight was not stated, the research can only look at assumptions and possibilities. For a 60-mana load or 29.86 kg, the wool weight per surface area would be 29.86 /192, 0.155 kg/sqm, 155 grams/sqm. Since the basket for 60-mana load would be about 0.5 meter diameter and 0.5 meter high, this could be used as an estimate of bolt length. The length of the rectangular bolt might be 192/0.5 or 384 meters. For a 90-mana load or 44.7 kg, the wool weight per surface area would be 44.7/192 , 0.233 kg/sqm, 233 grams/sqm. Since the basket for 90-mana load would have the same diameter (0.5 meter) and be about 0.7 meter high, this could be used as an estimate of bolt width. The length of the rectangular bolt might be 192/0.7 or 274 meters. For comparison, the cloth bolt in the BM 85194 math problem had a length of 288 meters. It seems the 90-mana packaging is ((288/274)-1) or 5% off, but more compatible with the BM 85194 problem. Given all the assumptions, the typical wool weight per surface area might be 233 grams/sq. meter (+-10 percent).

Another approach to find the weavers quota in terms of garment surface area per day is to examine the daily quotas for the reed mat weavers, reed basket weavers, and straw basket weavers. The daily quotas for the reed weavers and straw weavers are better understood than the daily quota for garment weavers. In the coefficient lists, there are four daily surface area quotas used for reed mats, large baskets, and small baskets. First, the daily quota in base 60 is extracted from the Sumerian coefficient list as a surface area and converted from Sumerian sar units to square meters. Then the appropriate surface density or surface area per kilogram can be scaled or estimated from the weight and surface coverage of a reed bundle.

The four daily quotas for reeds and straw can be converted into square meters. The first reed daily quota was 4_48, 4/60+48/3600,288/3600 sar, which converts to 2.88 square meters per workday. The first reed density constant approximates (4.5*2)/2.88 or 3.11 kilograms per square meters. The second reed daily quota was 3_45, 3/60+45/3600,225/3600 sar, which converts to 2.25 square meters per workday. The second reed density constant approximates (3.3*2.)/2.25 or 2.9 kilograms per square meters. The first straw daily quota was 3_36, 3/60+36/3600,216/3600 sar, which converts to 2.16 square meters per workday. The first straw density constant approximates (4.*.4977)/2.16 or 922 grams per square meters. The second straw daily quota was 6_40, 6/60+40/3600,400/3600 sar, which converts to 3.55 square meters per workday. The second straw density constant approximates (4.*.4977)/3.55 or 560 grams per square meters. The gist is that there are four daily surface area quotas used for reed mats, large baskets, and small baskets on the order of 2 to 3.5 square meters per workday.

The Sumerian lines for the straw density constants are 3_36 sa E2.KISIB IN.NU.DA (straw) at 922 gm/sqm and 6_40 sa E2.KISIB SE (barley straw) at 560 gm/sqm are of special interest in the weavers study. Both surface densities are within order of magnitude for recent cotton and woolen cloth. For example, the English wool broadcloth of 1570 CE. was 782 gm/sqm. Modern cotton bath towels range from 400 to 900 gm/sqm. The term in-nu-da means literally (straw-spin-side) and certainly is suggestive of weaving straw, but sufficiently close to wonder if "in" could include other fibers. Most of the URIII texts used a generic reed (GI) and reed bundles (sa GI) with the baskets. So while the coefficients or similar ancestor equivalencies were probably being used with "straw", a one to one track with possible wool coefficients would be difficult. While the straw and reed bundles were fixed at 4 manas per bundle giving the 560 gm/sqm for woven barley straw, it is of interest to spread the wool ration of 1 kg for men and 1.5 kg for women over the 3.55 square meters per workday for barley straw. The surface density for 1/3.55 and 1.5/3.55 fairly bracket the expected range for wool clothing from 281 to 422 gm/sqm.

In the texts, there are workdays cited for weavers (usz ), but unless the garment or material is cited, one can not be sure whether the textile is woolen cloth (tug usz), felt cloth (tug du), or linen (tug gada). One text cited a team of usz weavers on ziz wheat straw (related to emmer wheat) for about 2 percent of total workdays turned in on a foreman's large report. Just one tablet, but the inference is that some of the reed and straw quotas might have been used for "usz generic weavers" also.

Here's an example on how the eTCL weaver calculator might work in analysis of Sumerian clothing. The eTCL calculator can be used to estimate the expected weights of lam cloaks. The Sumerian tug2.lam cloak is well known from the Nippur lexical lists etc. In the current CDLI equivalency list (2014), there are two lines that cite either 10 tug2.lam cloaks per workday or 5 tug2.lam cloaks per workday ( an unreasonable disparity). After loading both 1/10 or 1/5 days into the eTCL calculator, the 1/10 workday leads to a calculation of 0.54 kg and the 1/5 workday leads to a calculation of 1.08 kg. From other texts, the typical lam cloak weighs from 1.00 kg to 1.068 kg. Elaborating, the lam cloak of the fourth class weighs about 1.00 kg and the lam cloak of the third class weighs about 1.068 kg. Since the Sumerians usually weighed wool to units of 1/60 mana or 0.008 kg, the significant figures of the kg weights are close to correct. So the figure of 10 tug2.lam cloaks per workday is suspect. The figure of 5 tug2.lam cloaks per workday and a weight of 1 kg to 1.068 kg is more compatible with the other texts on lam classes 4 and 3.

Continuing with using the eTCL calculator on lam cloaks, if one finds a lam cloak that weighs more than expected, then one can game on the eTCL calculator to estimate the workdays of the garment. Some of the lam cloaks average 1.3 kg from tablet KVM 32.1182, possibly garments for higher status. On successive calculations, enter the time series 0.2,0.21,0.22,0.23,0.24,0.25 for workdays in the eTCL calculator. A garment of 1.3 kg would take between 0.24 and 0.25 workdays for the weaver to complete. In terms of the URIII equivalency lists, the quota for the weaver might be 1/0.25 or 4 heavier lam cloaks per workday. The lam cloaks of 1.3 kg weight have the term zi-zi (cut? and cut?) as a line postscript.

Another interesting use of the Sumerian texts and the eTCL calculator is gaining insight on the Sumerian transportation system. As outlined in Englund's Command Economy, the Sumerians normally transported dry goods by porters or canal tow boats in large reed baskets . The standard transportation loads were 30 manas (1/2 man load), 60 manas (full man load) , or 90 manas (burro or ship) and usually packed into large baskets. The basket sizes were broken down into 30 liter, 60 liter, and 90 liter. In the Cdli tablet library, there is the line cdliatf20130330 1. 2(disz) tug2-mah siki gid2-bi 5(disz) ninda, which gives the length of 2 great rolls of wool cloth as total 5 nindas or 30 meters. The width was not given, but was probably one meter. With assumptions, the total surface area was L*W, 30*1, or 30 square meters. The total tug2 cloth appears close to a regular Sumerian standard, 30/32 or 94 percent of a sar (32 sqm). The total weight was estimated as 30/.375, 80 kg, or 160.7 manas. In modern terms, the cloth bolt was 80/2 or 40 kilograms. Each tug2.mah (cloth bolt?) was 160.7/2 or ~80 manas, just short of a standard 90 mana load. With spare packaging and a 90 liter reed basket weighing at least 4 manas, the tug2.mah was pretty close to the 90 mana standard.

The tug2-mah (great bolt) can be estimated in the eTCL calculator. The tug2-mah was 18 sqm (or 0.5 sar), 15 meters long, 1.2 meters wide (18/15). Set the workday initially at 1 and see one workday's wool as 5.4 kg. Load an initial estimate on the workdays as 40/5.4 or 7.4 workdays, push solve, and the gamed answer should be about 7.5 workdays of weaver labor. The calculator estimates the tug2-mah would use about 20 kg of madder dye, 220 kg of cleaning alkaline, 160 kg of cleaning oil, and cost 0.25 silver shekels in weaver labor. The 7.5 days of labor on the cloth bolt is close to a modern 7-day week. However, the Sumerians used a lunar calendar of 30 day months and the 7.5 days is more an artifact of 30/2/2 days, used in Sumerian accounts. Note the weaver labor for two rolls is another regular unit of 15 days (2*7.5 days equals 30/2 days).

Continuing with examples from the Sumerian transportation system, some tablets include inventories of standard packs of wool (or clothes) including lam du (felt cloaks), guzza du (felt neck wraps long shirts?), siki kur-ra tug usz-bar ( sashes of foreign wool), and siki ge usz-bar (sashes of black? wool). The tallies have units of 4*60+2 manas, or 242 manas. These big pack items and others listed appear rated as grades of wool, perhaps shipments of wool delivered to the weavers as suitable wool for the named line items. Making assumptions, the wool shipments to (and from) the weavers would be aligned with the standard loads of the Sumerian transport, namely 30 manas (1/2 manload), 60 manas (manload), 90 manas ( burro load?). At least some of the inventory tallies appear to be multiples of a manload of wool. Using the conversion units, a nominal manload would be 60 manas or 60*.4799, 28.8 kg. For the eTCL calculator, set the workday initially at 1, push solve for 1, and load an initial estimate on the workdays as 28.8/5.4 or 5.3 days for the weaver. The calculator estimated the weaver labor in the 28.8 kg pack as 0.18 silver piece. The quantities of madder root, cleaning alkaline, and cleaning oil are just hypothetical estimates. The Sumerian texts identify industrial goods transported by porter and ship, although not always the consumer.

The wool constant of 48 as a definition allows calculations of the processed wool per day away from averaging garments. The previous 10.7 manas of wool per workday was based on the averages of a foreman report. The fourth class lam cloak was produced on a quota of 5 per workday and was 48 lam garments to a 90 mana pack from the coefficient lists. The weaver quota of process wool would equal (5 tug2 per day*90 manas)/48 tug2, 9.375 manas, 9+22/60 manas, or 4.666 kg per workday. The generic formula for the weight of a garment would be ((5 tug2 per workday*90 manas)/48 tug2)/ (nnn garments per workday). The averaging of garment weights will continue to have a place in the analysis of Sumerian clothing, since one can not be sure that the weaver was using an accounting standard and there were many high status garments that had added decoration.

The madder constant (igi-gub gis-hab,hus,u2-hub) was 20. The math problem is determining how madder or other dyes were used in the Sumerian era (UrIII). Coefficients marked igi-gub were generally used as reciprocals in base 60. That is, the multiplier term for madder would the reciprocal 60/20 or 3. There was a Neo-Assyrian text or formula that multiplied manas of cloth by three to get the required manas of madder. The Neo-Assyrian text did not mention mordant, so perhaps the use of madder (300 %) is much higher than the typical use (50%) in modern times. Probably the Sumerian formula was required madder in manas equaled weight of cloth times (60/20), the (inverse) madder constant.

There some chemicals in the coefficient list which might have be used to bleach or mordant cloth as strong gypsum bleach (30/60), gypsum bleach (11_08/60), alum (20/60), and cleaning oil (20/60). The multiplier term for strong gypsum bleach would the reciprocal 60/30 or 2. Probably the Sumerian formula was required gypsum bleach in manas equaled weight of cloth times (60/30), the (inverse) gypsum constant. The required alum in manas equaled weight of cloth times (60/20), the (inverse) alum constant. For comparison, the Stockholm Papyrus (300-400 CE) used 50 % alum to weight of cloth. Contemporary natural dyers use 12 to 20% alum and sometimes use a second alum bath of 15% to fully treat cloth. Cleaning oil (id udu, butter oil), sand, grit, and alkaline ashes (naga) were used to clean clothes in Sumerian times. The appropriate Sumerian verb was naga sub, rub with ashes. Since oil was measured by volume rather than weight in manas, there is some uncertaincy in the (60/20) amounts of cleaning oil needed to clean a garment. However, most previous reports estimate the weight of cleaning oil was 3 to 5.5 times the weight of the garment and the weight of alkaline was 4 times the weight of the garment. For comparison in washing wool, the Stockholm Papyrus recommended 9 manas of fine grit earth for 1 mana of wool cloth and drying thoroughly after washing. For cleaning cloth, the Stockholm Papyrus (300-400 CE) mentioned rubbing ashes on cloth, then beating and trampling the cloth in preparation for cloth dye.

The modern dyer using natural dyes like red madder and yellow safflower has to make the same calculations as the ancient Sumerians. However, the modern terminology is different. The natural dyes are rated as percentage of weight of form, which is a measure of dye strength. The calculation for the required weight of dye is weight of cloth times the weight of form coefficient. For example in the eTCL calculator, the calculated mass of the garment (1.8 kg) is multiplied by the weight of form for red madder (50 %) to get the required dye 1.8*(50/100), or 0.9 kg.

Postscript May 2016. Recent cuneiform publications have given additional details of weaver work rates and loom size. These publications are from different cuneiform cultures, periods, and languages, so its difficult to modify the eTCL calculator to be consistent or conform to specific eras. The average loom was probably width of 4 meters and length of 4.5 meters and worked by 2 persons (ie. women). The latter Assyrian era has a specific letter asking for loom of 9 cubits by 8 cubits, converting to 4.5 meters by 4 meters. The median URIII products were 3.5 by 3.5 meters, 4 by 3.5, and up to 4.5 by 6 meters. For lam cloaks and average fabric surface density in metric units, calculations suggest 1700. / (3.5*3.5), 1700. / (4.5*3.5), 1700. / (4.5*4.), reducing to 138.77, 121.43 or 94.44 grams per square meters. Given loom rate of 0.5 meter per day, the loom production rate for the lam cloaks was the loom width 4.5 meters times 0.5 or 2.25 square meters per day. Multiplying the above tentative 1.75 sqm/day produced windows of 1.75*7 days = 12.25 sqm,1.75*15 = 26.25 sqm,1.75*21 = 36.75 sqm,1.75*30 = 52.5 sqm, meaning the sa-hi-a of 48 was possibly work over specified days used in accounting. As an alternate suggestion, perhaps the coefficient 48 is the area production of 48/60 sars or 25.6 sqm over 15 workdays. Similarly, the tug-mah might have been 15 meters length/ 0.5 meters per day or 30 days of production. Another gauze like fabric ranged 24 to 27 grams per square meters and production rate of 2 square meters per day. A heavy fabric density was about 3500/(2.59*1.25) or 1081 grams per square meter. From the UrIII texts, these fabrics were produced in teams of 15 to 21 women and the completion times were more workshop numbers of cooperative effort than individual piecework. For the calculator, probably the better approach is to start with garment weight and then estimate average materals and average work rates.

# calculations of average fabric surface density in URIII period set fabric_surface_density [eval expr 1700. / (3.5*3.5) ] # 138.77 grams/meter*meter set fabric_surface_density [eval expr 1700. / (4.0*3.5) ] # 121.43 grams/meter*meter set fabric_surface_density [eval expr 1700. / (4.0*4.5) ] # 94.44 grams/meter*meter set fabric_surface_density [eval expr 333. / (3.5*3.5) ] # 27 grams/meter*meter set fabric_surface_density [eval expr 333. / (4.0*3.5) ] # 24 grams/meter*meter set fabric_surface_density [eval expr 3500. / (2.6*1.25) ] # 1081 grams/meter*meter

Table 1, Garments text from Ur III

| garments | Ur III | ||||

|---|---|---|---|---|---|

| quantity | values | units | decimal workdays | units | comment |

| tug2-sagusbar | 1.7 | kilograms | 0.314 | workdays | |

| tug2-didila | 1.53 | kilograms | 0.283 | workdays | |

| total garments | 3.23 | kilograms | 3.3 | workdays |

Table 2, Sumerian coefficients for daily work quota, includes math problems and implied constants from tablets etc

| Sumerian coefficients for daily work rate, etc | ||||||

|---|---|---|---|---|---|---|

| daily work of one man etc in base 60 | transliterated name | english | decimal /fraction | reciprocal | comment | |

| 12 | u4, u4-1-se | hours of workday | 12 | 1/12 | 12 hours, common to several accounts and math problems | |

| 48 | igigub sig2 hi.a | coefficient wool | 48/60 | 60/48 | possibly daily quota of lam cloaks 4th class | |

| 40 | igigub sig2 hi.a | coefficient wool | 40/60 | 60/40 | possibly daily rate of loom, conv to (40/60)*6, 4.0 meters length of spun wool | |

| 10 | siki ku-bi-se | price of sheep wool | 10/60 | 60/10 | one silver shekel buys 10 manas of sheep wool, used in state accounting | |

| 30 | siki-ud ku-bi-se? | price of goat hair | 30/60 | 60/30 | one silver shekel buys 30 to 40 manas of goat hair, used in state accounting | |

| 1/60 | siki-se? | fraction of mana | 1/60 | 60/1 | 1/60 mana, 9 grams or 0.009 kg, smallest fraction weighing wool, used in craftsmen receipts | |

| 6 | u4 | 6 days for tug2 lam lugal (princely) | 6 | 1/6 | 6 days for tug2 lam , used in craftsmen receipts | |

| 2+nnn | lamhusu third class | (8+1/2+5/60)/4 mannas, 2.1458 | 1.0678 kg | workdays | ||

| 2 | lamhusu fourth class | 2 mana | 1 kg | workdays | ||

| 42 | tug2usz-bar ge6 42 tug2 per u4 ? | 42 woven items per day | 42 | 1/42 | 42 small items per day, used in state accounting | |

| 15 | tug2guz-za du 15 u4 per tug2 ? | 15 day | 15 | 1/15 | 15 days per high status tug2-guz-za robe , used in state accounting | |

| 4 | tug2ba-tab-duh-hu-um us2 4 u4 per tug2 ? | 4 day per item | 4 | 1/4 | 4 days per high status tug2-tab-duh robe , used in state accounting | |

| 2 | tug2ba-tab-duh-hu-um us2 4 u4 per tug2 ? | 2 day per item | 2 | 1/2 | 2 days per high status tug2-gazza robe , used in state accounting | |

| 7 | 7.5 workdays per kilogram at fuller shop? | 7 days per item | 7 | 1/7 | 7+30/60 workdays per kilogram of cloth at fullers shop, estimated from tables | |

| 3 | sig-bar | wool ration (lit. hair division) | 3 | 1/3 | variants sig-bar,sig-ba,tug2-ba are various wool rations or payments from 2,3,4 manas, used in state accounting | |

| 3 | tug2 NIG2.SAG.LAL.MUNUS nin | cloth_item head drapery female [for the] goddess | 3 | 1/3 | 3 workdays spent on headdress [for cultic statue?], used in state accounting | |

| 90 | tug2 guz-za du | cloth_item neck wrap built (felt?) | 90 | 1/90 | 90 workdays spent on neck wrap shirt?, high status garment, used in state accounting | |

| 1080 | tug2bar-dul5 gada lugal | cloth_item long gown linen princely | 1080 | 1/1080 | 1080 workdays spent on princely gown, used in state accounting | |

| 10 | tug2guz-za 4-kam us2 sur-ra | cloth_item neck wrap shirt? precious | 10 | 1/10 | 10 workdays spent on neck wrap, used in state accounting | |

| 42 | tug2usz-bar ge6 | cloth_item length middle wrap (belt, sash?) | 42 | 1/42 | one workday spent on 42 small cloth_items , used in state accounting | |

| 3? | tug-ku-ru-um | cloth_item morning[kuuru=grief] | 3? | 1/3 | (20/60?) workday spent on morning garb, need more examples | |

| 2 | tug2nig2-lam2 du | cloth_item cloak built [felt?] | 2 | 1/2 | two workdays spent on cloak, used in state accounting, "du" usually associated with felt | |

| 4 | tug2ba-tab-duh-hu-um | cloth_item ration grasp loosened joy?[celebration gown, cloak?] | 4 | 1/4 | 4 workdays spent on cloth_item, used in state accounting |

Table 3, Sumerian colored garments

| Sumerian colored garments/agents | English | possible agent |

|---|---|---|

| tug2-bar-si-hus | a red sash | |

| tug2-gu-e sig7-sig7 | green shawl | |

| tug2-bar-dul hus | a red garment, full-body garment | |

| tug2gu-e gun | a multi-colored shawl | |

| an-ta-dul | cloak | |

| tug2-im-su-a cloth | cloth treated with red clay | red clay |

| tug2 im-babbar-ra | whitened cloth, treated with gypsum | effectively, gypsum bleach |

| tug2-nin-lam hus | a red ceremonial garment | |

| tug2-u-ge6 | a black garment | natural? black wool , ku10, 'black' ? or kul, |

| most color/dye terms known from later cultures and eras, after 1200BCE | dub, verb. to dye fabrics | |

| síg-babbar | white wool (lit. white hair) | natural? white wool or gypsum bleached |

| im-pa-mun | dark clay used to color clothes | black or brown clay? |

| ni-ik-tum | poss. dye plant | associated with UrIII, ref. Akk.niqdu |

| sig-ge6 | black wool | associated with garments in UrIII |

| pus-a | something red | no examples of association |

| hus | something red | associated with garments in Nippur Lex. |

| sig7-sig7 | something yellow or green | associated with garments in Nippur Lex. |

| za-gin | something blue | associated with lapis lazuli stone |

| sig za-gin-ge6 | blue purple wool | Neo-Assyrian & Ugarit, associated with garments |

| sig za-gin-sa | red purple wool | Neo-Assyrian & Ugarit, associated with garments |

| sig za-gin | generic purple wool | Neo-Assyrian & Ugarit, associated with garments |

| gun | something multicolored | associated with garments in Nippur Lex. |

Table 4, Surface density of Modern or Historical Fabrics

| Modern fabrics | grams/m*m | grams/m*m | comment |

|---|---|---|---|

| double-knit wool | 420 | 420 | winter garment |

| gabardine worsted wool | 280 | 400 | winter garment |

| worsted wool | 180 | 250 | summer wear garment |

| wool, New Zealand pull-over | 320 | 320 | winter wear garment |

| wool, light weight base pull-over | 150 | 150 | winter wear garment |

| wool, 1570 CE, Essex broadcloth | 782 | 782 | winter wear garment |

| wool, 1570 CE, Mechelen broadcloths | 756 | 756 | winter wear garment |

| wool, 1570 CE, Ghent dickedinnen | 677 | 677 | winter wear garment |

| wool, 1570 CE, Bergues-St. Winoc | 260 | 260 | summer wear garment |

| wool, 1570 CE, Hondschoote small double-say | 266 | 266 | summer wear garment |

| wool, 1580 CE, Essex ‘New Draperies’ | 141 | 141 | summer wear garment |

| cotton duck | 200 | 250 | 200 or more |

| cotton cheese cloth, print cloth | 150 | 200 | less than 200 |

| cotton towel, gym | 300 | 400 | cheap, light weight |

| cotton towel, beach | 400 | 600 | medium weight |

| cotton towel, bath | 600 | 900 | heavy & luxury weight, most absorbent |

| Habutai Silk | 21.7 | 69.44 | |

| Chiffon Silk | 26.04 | 34.72 | |

| Crepe de Chine Silk | 52.08 | 69.44 | |

| Gauze Silk | 1.302 | 21.7 | |

| Raw silk | 151.9 | 173.6 | |

| Organza Silk | 17.36 | 26.04 | |

| Charmeuse Silk | 52.08 | 130.2 |

Table 5, Pseudocode and Equations using coefficients

| Pseudocode with some Equations | |

|---|---|

| namespace path {::tcl::mathop ::tcl::mathfunc} | |

| pseudocode: answer is mandays of labor or silver pieces +- error | |

| one mana of wool took 4 measures (mannas?) of alkali | |

| one mana of wool took 5.5 measures (5.5*2*sila?) of oil | |

| one kilogram of wool took 4 measures (kg?) of alkali | |

| one kilogram of wool took 5.5 measures (liters?) of oil | |

| surface density = surface area / weight |

Table 6, Formulas below are from modern times, more or less.

red madder kilograms = mass of cloth * (50/100) madder weight of form red brazilwood kg = mass of cloth * (50/100) brazilwood weight of form brown acaciawood kg = mass of cloth * (20/100) acaciawood weight of form brown henna kg = mass of cloth * (50/100) henna weight of form purple borage kg = mass of cloth * (75/100) borage weight of form alum kilograms = mass of cloth * (15/100) alum weight of form generic ashes mordant, one measure of ashes per one measure of cloth generic natural dye, two measures of pulverized bark, leaves, smashed berries per one measure of cloth generic required ashes = mass of cloth * (100./100.) natural weight of form generic required natural dye (bark, leaves, berries) = mass of cloth * (200./100.) natural weight of form Sometimes 2 or 3 fresh baths of mordant work better than one single and strong mordant bath. price? = raw materials + labor + profits price? = raw materials + heat process price? = raw materials + labor loss in cleaning raw wool kilograms = mass of cloth * (6.7/100.) modern estimate cleaning raw wool

Table 7, Formulas below are from ancient times, more or less.

Sumerian alum constant (sa na-sur-ra foreign salt) = 20?, may be 20/60 or 34/100 akaline kilograms = mass of cloth * (4.5) cuneiform alkaline constant cleaning oil kilograms = mass of cloth * (5.5) cuneiform oil constant red madder kilograms = mass of cloth * (300/100) NeoAssyrian ratio, no mordant red madder kilograms = mass of cloth * (50/100) Stockholm Papyrus, mordant prob. used Sumerian alum constant (sa na-sur-ra foreign salt) = 20?, may be 20/60 or 34/100 akaline kilograms = mass of cloth * (4.5) cuneiform alkaline constant cleaning oil kilograms = mass of cloth * (5.5) cuneiform oil constant orpiment coefficient was 54/60, inverse was 54/60 Sumerian orpiment = mass of wax/oil? * (60/54) , poss. yellow paint

Testcases Section

In planning any software, it is advisable to gather a number of testcases to check the results of the program. The math for the testcases can be checked by pasting statements in the TCL console. Aside from the TCL calculator display, when one presses the report button on the calculator, one will have console show access to the capacity functions (subroutines).

Testcase 1

| tug2-sagusbar | table printed in tcl format | |

|---|---|---|

| table printed in | tcl wiki format | |

| quanity | value | comment, if any |

| testcase number | 2 | |

| weight garment kilograms | 1.7 | |

| dyestuff percentage % | 50. | |

| wool kilograms | 1.7 | |

| madder dye kilograms | 0.85 | |

| cleaning oil liters: | 9.35 | |

| cleaning alkaline kilograms: | 6.8 | |

| labor workdays : | 7.000000000000001 | completion time for workshop |

| price of labor in silver: | 0.23333333333333336 | |

| price of labor in grain liters | 1.7 | |

| cloak length in meters: | 2.3864853865045976 | long side folded once |

| surface area in square meters: | 18.0 |

Testcase 2

| tug2-didila | table printed in tcl format | |

|---|---|---|

| table printed in | tcl wiki format | |

| quanity | value | comment, if any |

| testcase number | 2 | |

| weight garment kilograms | 1.7 | |

| dyestuff percentage % | 50. | |

| wool kilograms | 1.7 | |

| madder dye kilograms | 0.85 | |

| cleaning oil liters: | 9.35 | |

| cleaning alkaline kilograms: | 6.8 | |

| labor workdays : | 7.000000000000001 | completion time for workshop |

| price of labor in silver: | 0.23333333333333336 | |

| price of labor in grain liters | 1.7 | |

| cloak length in meters: | 2.3864853865045976 | long side folded once |

| surface area in square meters: | 18.0 |

Testcase 3

| table printed in | tcl format | |

|---|---|---|

| quanity | value | comment, if any |

| testcase number | 3 | |

| weight garment kilograms | 2. | |

| dyestuff percentage % | 50. | |

| wool kilograms | 2.0 | |

| madder dye kilograms | 1.0 | |

| cleaning oil liters: | 11.0 | |

| cleaning alkaline kilograms: | 8.0 | |

| labor workdays : | 8.23529411764706 | completion time for workshop |

| price of labor in silver: | 0.27450980392156865 | |

| price of labor in grain liters | 2.0 | |

| cloak length in meters: | 2.588506837359875 | long side folded once |

| surface area in square meters: | 21.176470588235293 |

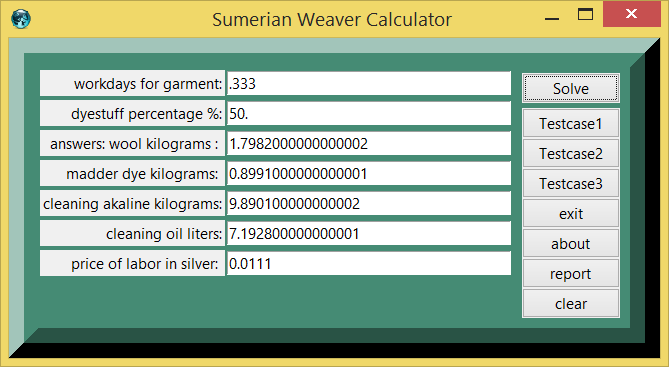

Screenshots Section

figure 1.

References:

- Cities of the Ancient World: faculty.washington.edu/modelski/WCITI2.html

- Women economic activities during the Ur III period, Bertrand Lafont (CNRS, Nanterre)

- [L1 ]

- Notes on Natural Dyeing, Priarie Fiber

- Natural Dyes, MAIWA handprints, natural_dyeing.pdf

- major paper in understandable prose,Equivalency Values and the Command Economy

- Robert Englund, UCLA , ucla.edu/staff/englund/publications/englund2012a.pdf

- Ur III Tablets in the Valdosta State University, search on cdli

- Cuneiform Digital Library Journal, search on Equivalency Values

- Ur III Equivalency Values, cdli.ox.ac.uk/wiki/doku.php?id=ur_iii_equivalency_values

- Especially, the Ur III Equivalency Values for tug2 (garments) and siki (wool) sections.

- The Sumerian keywords -bi, tug2, and siki search on the cdli

- are very effective, but major size files to download

- Hat Making and Felt Making, John Tompson, 1865

- at_the_cleaners,cdli.ox.ac.uk/wiki/doku.php?id=at_the_cleaners

- Hulin Collection in Oxford, Christopher Metcalf

- The Cuneiform Tablet Collection of Florida State University ,Eleanor Robson

- 2007:1 Kalamazoo, cdli.ucla.edu/pubs/cdlj/2007/001.html

- Mesopotamian Collection in the Kalamazoo Valley Museum,Andrea Seri

- Purple Dyes in Lazpa, Itamar Singer

- TEXTILES STUDIES: SOURCES METHODS Margarita Gleba University College London

- Wool Economy in the Ancient Near East and the Aegean Catherine Breniquet, C´ecile Michel

- Elements for a Comparative Study of Textile Production and Use in Hittite Anatolia and in Neighbouring Areas

- Giulia Baccelli, Benedetta Bellucci and Matteo Vigo

- Archaeological Textiles – A Need for New Methods of Analysis and Reconstruction, Maria Cybulska

- Geometric Division Problems, Quadratic Equations, and Recursive Geometric Algorithms in Mesopotamian Mathematics, Jöran Friberg

- Notes on Ur III Period Textile Tablets from Ur1 Richard Firth (University of Bristol, UK)

- Mesopotamian Mathematics 2100–1600 BC: Technical Constants in Bureaucracy and Education (Oxford Editions of Cuneiform Texts, 14), Oxford: Clarendon Press 1999.Eleanor Robson

- Mesopotamian mathematics, Eleanor Robson

- Textile Production and Consumption in the Ancient Near East, Marie Nosch, Henriette Koefoed, and

- Eva Strand

- Leichty, Erle. 1979. "A Collection of Recipes for Dyeing."

- In Studies in Honor of Tom B. Jones, edited by Marvin A. Powell

Appendix Code

appendix TCL programs and scripts

# pretty print from autoindent and ased editor

# Sumerian Weaver calculator

# written on Windows XP on eTCL

# working under TCL version 8.5.6 and eTCL 1.0.1

# gold on TCL Club , 9apr2014

# comment follows from gold, 12Dec2018

# pretty print from autoindent and ased editor

# Sumerian Weaver Calculator V2

# written on Windows XP on TCL

# working under TCL version 8.6

# Revamping older program from 10Nov2014.

# One of my early TCL programs on wiki.

package require Tk

namespace path {::tcl::mathop ::tcl::mathfunc}

frame .frame -relief flat -bg aquamarine4

pack .frame -side top -fill y -anchor center

set names {{} {weight garment kilograms:} }

lappend names {dyestuff percentage %:}

lappend names {answers: wool kilograms : }

lappend names {madder dye kilograms: }

lappend names {cleaning akaline kilograms:}

lappend names {cleaning oil liters:}

lappend names {optional:}

lappend names {price of labor in silver: }

foreach i {1 2 3 4 5 6 7 8} {

label .frame.label$i -text [lindex $names $i] -anchor e

entry .frame.entry$i -width 35 -textvariable side$i

grid .frame.label$i .frame.entry$i -sticky ew -pady 2 -padx 1 }

proc pi {} {

expr acos(-1)

}

proc about {} {

set msg "Calculator for Sumerian Weaver V2

from TCL ,

# gold on TCL Club, 12Dec2018 "

tk_messageBox -title "About" -message $msg }

proc self_help {} {

set msg " Sumerian Weaver V2

from TCL Club ,

# self help listing

# problem, Sumerian Weaver V2

# 4 givens follow.

1) alpha constant (ranges from .3 to 5.)

2) constant2 (optional, usually 1.):

3) expected number of fatal defects

per square mm (optional):

4) chip surface area square mm (optional):

# 3) & 4) used if both not zero

# Recommended procedure is push testcase

# and fill frame,

# change first three entries etc, push solve,

# and then push report.

# Report allows copy and paste

# from console to conventional texteditor.

# For testcases, testcase number is internal

# to the calculator and will not be printed

# until the report button is pushed

# for the current result numbers.

# >>> copyright notice <<<

# This posting, screenshots, and TCL source code is

# copyrighted under the TCL/TK license terms.

# Editorial rights and disclaimers

# retained under the TCL/TK license terms

# and will be defended as necessary in court.

Conventional text editor formulas

or formulas grabbed from internet

screens can be pasted into green console.

# gold on TCL Club, 12Dec2018 "

tk_messageBox -title "Self_Help" -message $msg }

proc calculate { } {

global answer2

global side1 side2 side3 side4 side5

global side6 side7 side8 testcase_number

global workday woolkg surfacearea

global madder oilcl alkaline dyestuff

global silverxpr grainxpr cloaklength

incr testcase_number

set woolkg [* $side1 1.0]

set workday [* $side1 [/ 7. 1.7 ] ]

set dyestuff $side2

set side3 $woolkg

set surfacearea [* $woolkg [/ 18. 1.7 ] ]

set sa $surfacearea

set side4 [* $woolkg [/ $dyestuff 100.]]

set side5 [* $woolkg 5.5]

set side6 [* $woolkg 4.]

set madder [* $woolkg .5]

set oilcl [* $woolkg 5.5]

set alkaline [* $woolkg 4.]

set grainxpr [* $woolkg 1.]

set cloaklength [* 1.125 [sqrt $surfacearea ] 0.5 ]

set side8 [* $workday [/ 1. 30. ]]

set silverxpr $side8

}

proc fillup {aa bb cc dd ee ff gg hh} {

.frame.entry1 insert 0 "$aa"

.frame.entry2 insert 0 "$bb"

.frame.entry3 insert 0 "$cc"

.frame.entry4 insert 0 "$dd"

.frame.entry5 insert 0 "$ee"

.frame.entry6 insert 0 "$ff"

.frame.entry7 insert 0 "$gg"

.frame.entry8 insert 0 "$hh"}

proc clearx {} {

foreach i {1 2 3 4 5 6 7 8} {

.frame.entry$i delete 0 end } }

proc reportx {} {

global side1 side2 side3 side4 side5

global side6 side7 side8 testcase_number

global workday woolkg surfacearea

global madder oilcl alkaline dyestuff

global silverxpr grainxpr cloaklength

console eval {.console config -bg palegreen}

console eval {.console config -font {fixed 20 bold}}

console eval {wm geometry . 40x20}

console eval {wm title . " Sumerian Weaver V2 Report, screen grab and paste from console 2 to texteditor"}

console eval {. configure -background orange -highlightcolor brown -relief raised -border 30}

console show;

puts "%|table printed in| tcl format|% "

puts "&|quantity| value| comment, if any|& "

puts "&|testcase number| $testcase_number||& "

puts "&|weight garment kilograms | $side1 ||&"

puts "&|dyestuff percentage % | $side2||& "

puts "&|wool kilograms| $side3||& "

puts "&|madder dye kilograms| $side4 ||&"

puts "&|cleaning oil liters:| $side5||& "

puts "&|cleaning alkaline kilograms:| $side6 ||&"

puts "&|labor workdays :| $workday | completion time for workshop |&"

puts "&|price of labor in silver:| $side7 ||&"

puts "&|price of labor in grain liters| $grainxpr ||& "

puts "&|cloak length in meters:|$cloaklength|long side folded once|&"

puts "&|surface area in square meters:|$surfacearea||&"

}

frame .buttons -bg aquamarine4

::ttk::button .calculator -text "Solve" -command { calculate }

::ttk::button .test2 -text "Testcase1" -command {clearx;fillup .333 50. 0.333 .1665 1.83 1.3 0. .045 }

::ttk::button .test3 -text "Testcase2" -command {clearx;fillup 1.7 50. 1.7 .85 9.4 6.4 0. .22 }

::ttk::button .test4 -text "Testcase3" -command {clearx;fillup 2. 50. 2.0 2.7 11.7 8.6 0. .27}

::ttk::button .clearallx -text clear -command {clearx }

::ttk::button .about -text about -command about

::ttk::button .self_help -text self_help -command { self_help }

::ttk::button .cons -text report -command { reportx }

::ttk::button .exit -text exit -command {exit}

pack .calculator -in .buttons -side top -padx 10 -pady 5

pack .clearallx .cons .self_help .about .exit .test4 .test3 .test2 -side bottom -in .buttons

grid .frame .buttons -sticky ns -pady {0 10}

. configure -background aquamarine4 -highlightcolor brown -relief raised -border 30

wm title . "Sumerian Weaver Calculator V2"

Pushbutton Operation

For the push buttons, the recommended procedure is push testcase and fill frame, change first three entries etc, push solve, and then push report. Report allows copy and paste from console.

For testcases in a computer session, the eTCL calculator increments a new testcase number internally, eg. TC(1), TC(2) , TC(3) , TC(N). The testcase number is internal to the calculator and will not be printed until the report button is pushed for the current result numbers (which numbers will be cleared on the next solve button.) The command { calculate; reportx } or { calculate ; reportx; clearx } can be added or changed to report automatically. Another wrinkle would be to print out the current text, delimiters, and numbers in a TCL wiki style table as

puts " %| testcase $testcase_number | value| units |comment |%" puts " &| volume| $volume| cubic meters |based on length $side1 and width $side2 |&"

---

Comments Section

Please place any comments here with your wiki MONIKER and date, Thanks.gold12Dec2018

AMG: Please remember that for wiki formatting, any text in [brackets] needs to have those brackets doubled up ("[[" and "]]]"), or else the text will be treated as a page link.